From Design to Delivery: Procuring Packaged Plant Rooms UK with Confidence

Understanding your project objectives, assessing technical proficiency, and confirming adherence to UK norms are the first steps in locating the top supplier of packaged plant rooms in the UK. A systematic strategy helps guarantee that the packaged plant rooms UK professional you have selected can provide a dependable, effective and completely compliance solution for your project or development.

Understanding Packaged Plant Rooms in the UK

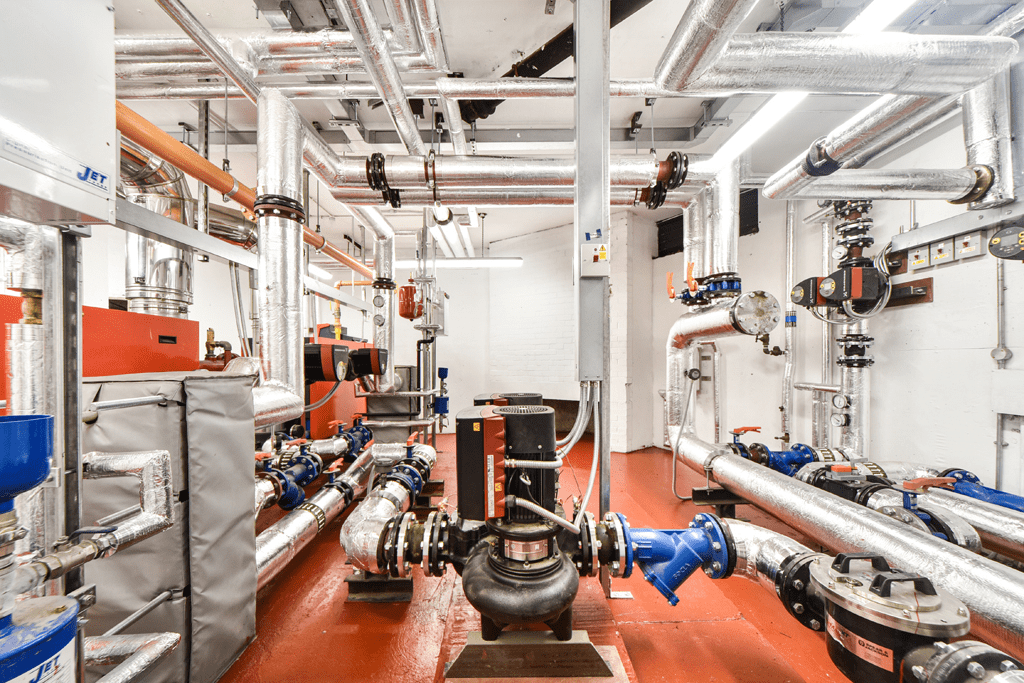

Understanding what packaged plant rooms UK providers truly offer and how these offsite-built energy centres vary from conventional, site-built plant areas is crucial before starting any procurement process. at a nutshell, packaged plant rooms UK are independent modules that comprise mechanical, electrical, and control equipment for services like power, ventilation, hot and cold water, heating, and hot water. These modules are manufactured at a factory and delivered to the site ready for final connection.

Compared to traditional on-site assembly, quality and uniformity can be easier to accomplish because packaged plant rooms UK are manufactured under controlled conditions. Because they save on-site manpower, decrease program schedules, and assist eliminate health and safety issues in crowded or complex projects, packaged plant rooms are now preferred by many construction and building services teams.

Specifying the needs for your project

A precise written description of the performance and capacity requirements for your project is the first step in choosing suppliers of packaged plant rooms in the UK. The necessary loads for heating, hot water, cooling, or power, any redundancy plan, design temperatures and flow rates, and whether the packaged plant rooms UK must work in tandem with current systems or independently should all be included.

In order for prospective partners in packaged plant rooms UK to design within your available footprint, access routes, and cranage limits, it is also essential to document physical site constraints. You can talk about installation phasing, temporary services, and future expansion needs with one or more contenders for packaged plant rooms UK early on. These discussions will impact enclosure sizes, door positions, and internal layouts.

Verifying technical proficiency and expertise

Once the objective is established, focus shifts to the technical proficiency of possible suppliers of packaged plant rooms in the UK and proof that they can reliably construct complicated systems. Mechanical, electrical and controls experts that comprehend building services design principles and are capable of producing intricate drawings, schematics and control philosophies are often employed by well-known producers of packaged plant rooms in the UK.

When shortlisting suppliers of packaged plant rooms in the UK, experience in a variety of industries is also helpful because applications in the healthcare, education, leisure, and residential sectors may have varied regulatory and operational demands. A solid history of supplying packaged plant rooms in the UK for projects with comparable scope and complexity to yours shows the supplier is knowledgeable about common coordination difficulties and performance benchmarks.

Confirming accreditation and compliance

Compliance with UK laws and standards is essential when evaluating any manufacturer of packaged plant rooms in the UK, particularly when gas, pressure systems or hazardous regions are involved. Many customers may seek proof, backed up by factory inspection and test records, that packaged plant rooms in the UK are designed and manufactured under acknowledged quality management standards.

Beyond broad quality guidelines, suppliers of packaged plant rooms in the UK should show that their designs can satisfy all applicable building rules, energy performance standards, and safety codes for the intended application. Packaged plant rooms UK must be evaluated in accordance with expert advice for projects requiring flammable fuels or potentially explosive atmospheres, and certification and risk assessments must be included in the handover package.

Evaluating the adaptability and personalisation of the design

Given the unique technological and spatial limitations of each building or renovation project, the ideal partner for packaged plant rooms UK will provide a high level of design freedom. Modern industries can set up packaged plant rooms UK as multi-section energy centres, acoustic units, portable modules, or fixed installations, depending on whether scalability, mobility, permanence, or noise control are the top priorities.

Enquire about how a supplier customises its packaged plant rooms UK to address concerns like tight noise limitations around nearby properties, limited headroom, restricted access, or delicate façades during the tender or design phase. Manufacturers of packaged plant rooms in the UK can frequently modify enclosure finishes, door locations, internal equipment configurations, and maintenance access points to meet performance and architectural requirements.

Assessing the capacity for off-site manufacturing

The majority of work is done offsite, which is a key benefit of packaged plant rooms in the UK. Therefore, assessing manufacturing capabilities is essential to any supplier review. Steelwork, enclosures, pipes, wiring, and controls assembly are often handled under one roof by facilities that specialise in packaged plant rooms in the UK. This allows for improved coordination and lowers the possibility of disciplinary conflicts.

When comparing suppliers of packaged plant rooms in the UK, thorough pre-commissioning reduces site time and helps prevent late faults, thus robust factory acceptance testing is another crucial consideration. Clients can be assured that their packaged plant rooms UK will seamlessly connect with downstream systems by seeing pressure testing, functional checks, and control simulations before to delivery.

Taking into account the program, installation, and logistics

Particularly on limited or city-center sites, the logistics and installation strategy might set one vendor of packaged plant rooms UK apart from another. The manufacturer should offer instructions on transportation routes, lifting requirements, and any temporary work or foundations required, as the majority of packaged plant rooms in the UK arrive as huge modules or parts.

Although on-site installation typically takes less time than traditional plant construction, there may still be a lot of collaboration with other trades, so you should examine how UK packaged plant room providers schedule interface points, outages, and commissioning periods. When a provider of packaged plant rooms UK has a clear schedule that includes offsite build, delivery, setting to work, and performance testing, it shows that they understand the construction sequence and may assist in de-risking your critical path.

Comparing lifecycle performance, value, and cost

Any selection must consider price, but when operational and maintenance considerations are taken into account, the cheapest quote for packaged plant rooms in the UK might not offer the best long-term value. In addition to capital costs, comprehensive proposals for packaged plant rooms in the UK should include control strategies, indicative efficiency levels, and prospects for future upgrades to lower-carbon technology.

Examine the degree to which proposals from various UK manufacturers of packaged plant rooms clarify scope boundaries, exclusions, and assumptions. Particularly on mission-critical locations where downtime must be minimised, transparent documentation regarding spare parts, aftercare, and technical support can have a substantial impact on the whole-life cost profile of packaged plant rooms UK.

Examining future-proofing, assistance, and aftercare

Especially for complex systems with intricate controls, the assistance you receive after practical completion may be just as crucial as the initial delivery of packaged plant rooms UK. Because it guarantees the system will continue to function as intended, many clients prefer suppliers of packaged plant rooms in the UK that provide commissioning assistance, operator training, and choices for continuing maintenance.

As many businesses strive for net zero and may eventually want to incorporate heat pumps, solar thermal, or other low-carbon technologies, futureproofing is another important consideration when selecting packaged plant rooms in the UK. Phased upgrades, spare plant capacity, or additional modules will be possible with a well-designed packaged plant rooms UK solution, allowing the system to develop without requiring significant reconstruction.

Creating a shortlist and choosing a winner

Once technical, commercial, and program information has been acquired, you may start to reduce the field to a select few qualified suppliers of packaged plant rooms UK. At this point, it is frequently beneficial to set up virtual tours or factory visits so that interested parties may observe how potential partners create, produce, and test their packaged plant rooms UK in real-world settings.

Design quality, proof of compliance, delivery history, and the quality of the working relationship you anticipate with the selected expert in packaged plant rooms UK should all be taken into consideration when making your final decision. In order to produce building services infrastructure that is safe, effective, and robust, project teams can choose a supplier of packaged plant rooms UK by adhering to a defined approach and concentrating on capability, communication, and long-term support.