Designing for Reliability: The Role of SKF 626 in Contemporary Engineering Solutions

Deep groove ball bearings are one of the most adaptable components in modern engineering, providing a balanced combination of load capacity, speed capabilities, and compact size. Their applications are wide-ranging, including automotive, household appliances, power equipment, and industrial machines. In such applications, a bearing’s performance is frequently linked to its ability to sustain radial and axial loads with little friction and consistent reliability over a long service life. The SKF 626 series is a popular choice in this market, since it exemplifies the practical characteristics that engineers seek: strong inner and outer rings, precise raceways, and a design that tolerates minor misalignment without sacrificing performance. The presence of a bearing, such as the SKF 626, in a rotating assembly can affect vibration characteristics, load distribution, and overall efficiency, making it an obvious starting point for any discussion of modern bearing utilisation.

Deep groove ball bearings are widely used to support wheel hubs, alternators and gearbox components. The SKF 626 variation is commonly used for mild to moderate loads where compact size and low maintenance needs are critical. The combination of SKF 626 with the suitable lubrication regime lowers friction and wear, resulting in better fuel economy and smoother performance. Components such as steering columns and window regulator mechanisms benefit from the consistent rotational motion provided by a reliable deep groove bearing. In each scenario, the selection of SKF 626 is influenced by a mix of dimensional compatibility, radial rigidity, and the capacity to endure centrifugal forces generated at greater running speeds. The final result is a long-lasting solution that helps extend service intervals and reduces the possibility of unexpected downtime.

Household appliances rely significantly on bearings that can run silently and continuously with little variation in performance. Deep groove ball bearings provide the balance required for drum motors, fans, and compact compressors, where space and energy economy are crucial. The SKF 626 family is commonly used in small to medium-sized appliances due to its consistent performance and the availability of appropriate seals and shields. To achieve silent operation with SKF 626, pick an appropriate seal geometry and lubricant type, which helps avoid dust and moisture contamination while maintaining consistent friction coefficients. The end result is a more reliable appliance lifecycle, lower maintenance costs, and higher user happiness, all of which are dependent on the quality of the bearing design and its interaction with other components.

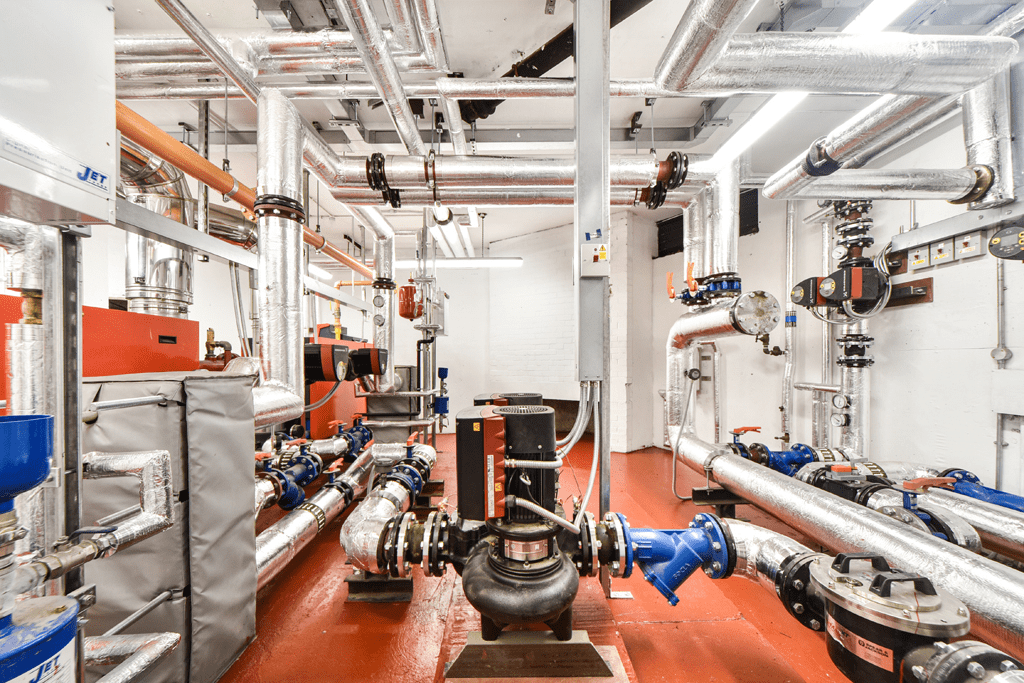

Deep groove ball bearings have a wide range of uses in industrial machinery, including conveyors, press lines, gearboxes, and pumps. The SKF 626 bearing can play a critical role in systems when compact dimensions are advantageous and axial thrust is mild. A well chosen SKF 626 ensures smooth start-up conditions, steady running temperatures, and a predictable wear profile even under vigorous loading. In many cases, engineers may customise the lubrication strategy—grease or oil—and monitor crucial metrics like vibration and temperature to ensure the bearing remains within specification throughout its service life. This approach emphasises the need of a comprehensive bearing program, with SKF 626 serving as a dependable building piece within larger reliability-focused maintenance schemes.

The aviation industry sets stringent standards for bearings used in auxiliary systems, climate control equipment, and some mechanical actuators. While high-speed performance is an important goal, many deployments emphasise endurance and dependability in difficult conditions. In this context, the SKF 626 series is suitable because to its geometry, clearance, and compatibility with protective seals designed to prevent the intrusion of corrosive or particle debris. The bearing’s adherence to strict tolerances helps guarantee that dynamic alignment remains within acceptable limits, lowering the risk of rotor imbalance or cascading vibration in important systems. The decision to use SKF 626 in aviation-related components is frequently based on a balancing between performance margins and maintenance practicalities, with the understanding that each component contributes to overall safety and mission readiness.

Deep groove ball bearings are used in auxiliary equipment, pumps, and fans to assist plant operations in the energy generating industry. The SKF 626 bearing is ideal for applications that need limited space and low radial loads while operating at high temperatures. To achieve consistent performance, choose appropriate lubrication classes, such as high-temperature greases, and install strong sealing solutions to restrict oil leakage and contamination. SKF 626 can retain consistent friction properties across temperature ranges, which aids in the stabilisation of gear and bearing meshes in rotating equipment. For engineers, this means better predictability of equipment availability and a simpler plan for maintenance shutdowns, both of which contribute to better utilisation of generation assets.

The construction industry creates difficult settings in which equipment must withstand dust, vibration, and varying loading spectrum. Deep groove ball bearings, such as the SKF 626, are commonly used in compact winches, hydraulic pumps, and portable power equipment that must operate consistently in the field. The combination of a proven raceway shape and a strong cage construction in SKF 626 ensures consistent performance under changing loads. Practically, this means longer component life and less downtime due to bearing problems. Engineers can also use SKF 626 with strengthened shields or seals to resist contamination on dusty job sites, maintaining lubrication and prolonging service life in difficult operating conditions.

Precision and quiet operation are critical features of medical equipment and laboratory instruments. While many devices use purpose-built bearings, a well-chosen deep groove variation, such as SKF 626, can strike the right mix between sensitivity and longevity. In these cases, the bearing tolerances are important because they affect the stability of micro-positioning stages and spinning elements within analytical instruments. SKF 626 is frequently chosen not only for its load-carrying capacity, but also for its low noise and vibration levels, which add to user comfort and measurement accuracy over time. To maintain a clean interior environment, the selection method often comprises matching the bearing’s dimensional parameters to the instrument’s housing and seals.

Rail systems and urban transit railcars also require strong bearings to sustain wheel assemblies, traction equipment, and auxiliary mechanisms. Deep groove ball bearings, such as the SKF 626, are regarded for their resistance to misalignment and ability to last in space-constrained assemblies. In rolling stock, the bearing must withstand prolonged operation at a variety of speeds and loads while resisting the effects of environmental exposure. The SKF 626 option in such assemblies can be combined with accurate mounting techniques and customised lubrication regimes to ensure consistent performance over years of service, allowing rail vehicles to move with confidence and minimising the workload on maintenance teams.

The deep groove family’s potential uses are becoming more diverse as bearing technology evolves. Tighter tolerances, superior materials, and smarter lubrication techniques are all possible thanks to modern production processes, which increase the capabilities of bearings like the SKF 626. With correct pre-load, fit, and alignment, SKF 626 can provide constant radial motion, low friction, and dependable axial handling in a small package. Engineers who embrace these developments frequently discover that well-chosen bearing families, such as SKF 626, integrate more easily into digital condition monitoring systems, where vibration signatures and temperature trends help predict impending wear and schedule maintenance activities before failures occur.

In practice, choosing a bearing like the SKF 626 requires careful consideration of operating conditions, lifecycle costs, and maintenance philosophies. The decision-making process takes into account loads, speeds, lubrication types, seal configurations, and environmental conditions that affect corrosion resistance and contaminant control. Engineers can increase reliability, energy efficiency, and uptime by adopting a design mindset that views the bearing as a component of a larger system. SKF 626 is an important case study in this regard, demonstrating how a well-designed bearing shape can produce substantial benefits across a wide range of applications while remaining compatible with a wide range of housings, shafts, and mounting configurations.

As maintenance tactics progress, bearings such as the SKF 626 play an increasingly important part in predictive maintenance programmes. Operators can use monitoring techniques such as vibration analysis, thermography, and wear particle evaluation to create condition-based intervals that improve lubrication regimens and part replacement scheduling. The consistent baseline performance of the SKF 626 leads to clearer diagnostic signals, allowing specialists to discern between typical operating characteristics and true defects. In reality, this results in more exact maintenance windows, fewer unnecessary part changes, and a demonstrated decrease in total cost of ownership during the bearing’s service life.

The history of deep groove ball bearings is incomplete without mentioning the significance of quality control in manufacturing and supply. The uniformity of raceway finishes, bore and outer diameter accuracy, and seal reliability all contribute to the SKF 626’s real-world performance in client assemblies. Engineers may trust on SKF 626 as a robust component within important machines since their suppliers maintain strict inbound inspection, traceability, and dimensional tolerances. In a market where even minor deviations can have a significant impact, the predictability of a well-specified bearing choice contributes to the long-term performance, safety, and productivity of industries.

To summarise, deep groove ball bearings play an important role in the modern engineering toolset, providing a versatile solution for a wide range of rotating equipment. The SKF 626 bearing, with its sturdy shape, adjustable seals, and dependable performance, exemplifies how a single bearing family can support a wide range of applications, from automobile components and household appliances to industrial machinery and specialised equipment. The key to success is to match the bearing’s capabilities to the application’s specific requirements, which include load direction, speed, contamination control, and maintenance philosophy. Engineers may achieve long-lasting, efficient, and dependable operation that withstands the rigours of real-world use by incorporating SKF 626 into a comprehensive design and maintenance approach.